Modified type - for o-ring seal.nab 301 wrote:

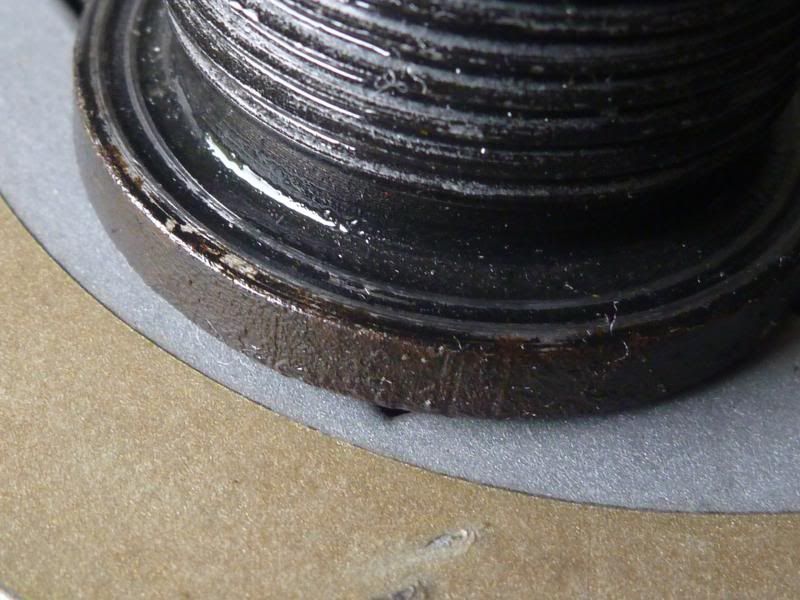

There's never been one on mine, never really thought about ita poor quality pic I took today.

Could be worth a good clean and condition of O-ring before replacing.

Al

Moderators: slparry, Gromit, Paul

Modified type - for o-ring seal.nab 301 wrote:

There's never been one on mine, never really thought about ita poor quality pic I took today.

Really Al?Blackal wrote:Modified type - for o-ring seal.nab 301 wrote:

]

Could be worth a good clean and condition of O-ring before replacing.

Al

With all the recent talk of EP greases, this took my mind back to the above question, posed by tapio.Corvus wrote:I wondered the same. In fact I'm wondering now, over a beer and not going to be losing sleep either!Tapio wrote:Service manual states that the gearbox and end gear requires hypoid oil.

The difference between a regular bevel gear and a hypoid gear is that in the hypoid gear, the center of the pinion is offset from the center of the crown wheel.

See pic: http://en.wikipedia.org/wiki/Hypoid

This requires special oil, due to the contact point twisting as it’s rolling along the cogs.

But the end gear is not a hypoid gear! And the gearbox doesn’t even have a bevel gear (obviously, since the crankshaft is longitudinally mounted) in there!

So why does BMW say that that the gears require hypoid oil?

Must add: it’s not that I’m losing any sleep over this matter, I’m just wondering if anybody has any info on this.

//T

I believe a hypoid gear has a degree of sliding, similar to a worm gear, whereas a helical gear, spur gear, bevel gear and I think also a spiral bevel gear all have a rolling action on a constant pitch circle.

If I've got that right will there be more oil shearing in a hypoid, requiring a different oil? Still, that doesn't explain why bmw need it in their gearboxes and final drives!

The gearbox has a torsional ramp action shock absorber. Would this need a hypoid gear oil? Not sure what is in the final drive which needs it. The spline?

At the end of the day maybe they found that they can increase tooth loads (pressure) by using this type of oil, thereby able to use smaller gears?

Just speculation though.

My understanding of tooth contact with helical cut gears is different to yours. I've always understood that they will carry higher loads for a given width because more area is in contact, not less.Tapio wrote:Achieving smaller gears with EP additives?

No, I really don't think so. Of course, if you have straight cut, spur type gears, then making gears wider would lessen the risk of having metal-to-metal teeth contact.

But not when it comes to helical gears. In a helical gear you don't have a full line of contact (like in spur gears) but a point of contact that moves along the tooth face as the gears turn. So making the gears wider doesn't help att in reducing oil film pressure in the contact point.

In fact, I don't think metal-to-metal contact is a big issue in gear tooth geometry designing. A much bigger issue is NVH. So i've heard. Gears can whine a lot if this is not adressed. A good example is the whining you can hear in a car with a manual transmission going in reverse. reverse usually is a non syncronised spur gear.

I have done hundreds of failure analysis on spiral cut hypoid gears when I worked at Getrag.

They were shipped to us from Land Rover's proving ground in Solihull.

Metal-to-metal contact was never a problem. Maybe one gear in a hundred had some very small pitting in the contact faces. You needed a magnifying glass to see it.

interesting link , I never realised that helical gears produced very high axial loadsCorvus wrote:http://automotivethinker.com/transmission/straight-cut-gears-vs-helical/

Depends on the helix angle. Use trigonometry to find the value as a proportion of the tangential load. The axial load load created by a small helix angle could sometimes be carried quite adequately by a deep groove ball bearing. So it needn't always be very high. Usually it's relatively small. Imo.nab 301 wrote:interesting link , I never realised that helical gears produced very high axial loadsCorvus wrote:http://automotivethinker.com/transmission/straight-cut-gears-vs-helical/

Also, on the above link, the component forces shown are not, to my way of thinking, the highest component. He shows the axial and separating components, whereas, in most applications the highest component by far is almost acting tangentially, but is tilted by the tooth pressure angle, which lengthens the vector line. Fig 8.1 on this link illustrates it perfectly. Force Fn they are calling it. This same force is felt at the bearings carrying the shaft (but in the opposite direction), to my way of thinking.nab 301 wrote:interesting link , I never realised that helical gears produced very high axial loads

From your first link:Corvus wrote:My understanding of tooth contact with helical cut gears is different to yours. I've always understood that they will carry higher loads for a given width because more area is in contact, not less.

Wikipedia:When two teeth on a helical gear system engage, the contact starts at one end of the tooth and gradually spreads as the gears rotate, until the two teeth are in full engagement.

ok, so the contact point moves, but its never utilizing the whole width of the tooth face. So how can you decrease the risk of metal-to-metal contact by widening the gears?With parallel helical gears, each pair of teeth first make contact at a single point at one side of the gear wheel; a moving curve of contact then grows gradually across the tooth face to a maximum then recedes until the teeth break contact at a single point on the opposite side

Gear tooth teamwork?Tapio wrote:

...........ok, so the contact point moves, but its never utilizing the whole width of the tooth face. ..............

My take on things.Tapio wrote:Achieving smaller gears with EP additives?

No, I really don't think so. .........

.........In fact, I don't think metal-to-metal contact is a big issue in gear tooth geometry designing. .................