The dreaded clutch/final drive failure?

Moderators: slparry, Gromit, Paul

The gearbox shaft lengths have to be measured between certain points and shimmed if needed. The shims are fitted onto the shafts..Bruno wrote:Is a gearbox rebuild a straightforward strip and rebuild or is there lots of shiming involved like an airhead?

I see that an input shaft from M/works is £170+.

Mk

They don't need to be measured in the gearbox case like the airhead gearboxes do.

-

Rumplefunkskin

- Posts: 15

- Joined: Sat Dec 21, 2013 1:17 pm

Right, so finally some progress has been made.

Got the gearbox apart and rebuilt all in one fell swoop last weekend, and have spent most of the week getting everything back on the bike ready to do a test.

Fired her up (eventually this afternoon), but it's not selecting/engaging the gears properly now. The gearbox was able to select gears fine once it had been rebuilt, and it's only since the clutch hydraulic hoses were reattached that it's stopped doing that. Thoughts are that I've done a poor job of bleeding the clutch?

Any tips on getting a good bleed and the air out of the system? I've got the Motorworks bleed nipple adapter, but I'm fairly sure there's still air in the system. The lever feels too soft.

Was nice to hear her fire up again though. Love that sound!

Got the gearbox apart and rebuilt all in one fell swoop last weekend, and have spent most of the week getting everything back on the bike ready to do a test.

Fired her up (eventually this afternoon), but it's not selecting/engaging the gears properly now. The gearbox was able to select gears fine once it had been rebuilt, and it's only since the clutch hydraulic hoses were reattached that it's stopped doing that. Thoughts are that I've done a poor job of bleeding the clutch?

Any tips on getting a good bleed and the air out of the system? I've got the Motorworks bleed nipple adapter, but I'm fairly sure there's still air in the system. The lever feels too soft.

Was nice to hear her fire up again though. Love that sound!

Well done! Good job you tried the gear selection with the box still out. You do now have the best quality full synthetic, correct oil in there? Next, remove the clutch lever, or arrange it to get the air bubbles from the hose banjo to creep up into the reservoir. Ideally, you will have someone pull in the clutch lever, while you open the hose nipple. I had to do it on my own, it takes time. The gears should select easily without the engine running, try that too; clutch and change gear - might need some wheel movement to make it easier. You are most of the way there now.

Oyster. 1999 R1100S. Almost original.

-

Rumplefunkskin

- Posts: 15

- Joined: Sat Dec 21, 2013 1:17 pm

Thanks for the words of encouragement Oyster. So close, yet so far it seems! Have definitely got the finest premium grade oil in there, so hopefully it is just the poor clutch bleed letting it all down.

I've been bleeding from the bleed point on the back of the gearbox and taking the air out of the system that way, rather than getting the air bubbles up to the reservoir on the bars. Is there much difference between the two methods for the clutch?

I've been bleeding from the bleed point on the back of the gearbox and taking the air out of the system that way, rather than getting the air bubbles up to the reservoir on the bars. Is there much difference between the two methods for the clutch?

-

Rumplefunkskin

- Posts: 15

- Joined: Sat Dec 21, 2013 1:17 pm

Clutch based hell!

Aaaaand I'm stuck it seems..... I've bled the clutch, managed to get a fair bit more air out and the clutch lever has a nice firm feel to it now. BUT! it still isn't engaging with the engine once the clutch levers been let out?

I can select all the gears rocking the bike forward, and can let the clutch out with the bike in gear, but nothing happens. There's no feeling of the engine enaging with the gearbox at all, and certainly nothing that suggests the bike is going to move.

I'm at a loss now. I can only imagine it's the clutch that's letting it down. Even though it feels as though it's bled properly, would that be the cause of drive from being taken from the engine?

I can select all the gears rocking the bike forward, and can let the clutch out with the bike in gear, but nothing happens. There's no feeling of the engine enaging with the gearbox at all, and certainly nothing that suggests the bike is going to move.

I'm at a loss now. I can only imagine it's the clutch that's letting it down. Even though it feels as though it's bled properly, would that be the cause of drive from being taken from the engine?

Re: Clutch based hell!

Just to confirm you've no drive at all ? That is , engine off, select a gear , can you turn the engine over with the rear wheel? If not I guess it means working from the bevel box driveshaft connection forwardsRumplefunkskin wrote: I can select all the gears rocking the bike forward, and can let the clutch out with the bike in gear, but nothing happens. There's no feeling of the engine enaging with the gearbox at all, and certainly nothing that suggests the bike is going to move.

?

If it is the clutch operation , could it be a bent pushrod ?

_________________

Nigel

Keep smiling, it makes people wonder what you've been up to!

1999 R1100s (mandarin) '

2018 DL 250V Strom

2019 CB125F Honda.

MZ301 Saxon Fun ( currently retired)

'03 Bullet 65 project..

Nigel

Keep smiling, it makes people wonder what you've been up to!

1999 R1100s (mandarin) '

2018 DL 250V Strom

2019 CB125F Honda.

MZ301 Saxon Fun ( currently retired)

'03 Bullet 65 project..

-

Rumplefunkskin

- Posts: 15

- Joined: Sat Dec 21, 2013 1:17 pm

Nope, no drive at all. Bike can be in gear with the engine off, and can be easily pushed around. Doesn't feel as of it's turning the engine over at all.

Pushrod looked fine when it was out of the box. Checked it against a flat surface and seemed straight and true.

At a loss as to where to go from here, short of tearing it down again and trying to diagnose the problem. All shafts were good, everything looked and felt like it was re-engaged properly on the rebuild. Can't see another point other than the clutch that would prevent the lack of drive?

Pushrod looked fine when it was out of the box. Checked it against a flat surface and seemed straight and true.

At a loss as to where to go from here, short of tearing it down again and trying to diagnose the problem. All shafts were good, everything looked and felt like it was re-engaged properly on the rebuild. Can't see another point other than the clutch that would prevent the lack of drive?

After the gearbox rebuild, each gear could be selected and the shafts at each end turned? If so, gearbox is ok. The only weak point left now is the clutch. Was it taken apart? Plate arrangement is significant. After that, the clutch operating rod and slave cylinder; but for no drive, it would be under pressure, holding the clutch open.

Oyster. 1999 R1100S. Almost original.

-

Rumplefunkskin

- Posts: 15

- Joined: Sat Dec 21, 2013 1:17 pm

After the rebuild each gear could definitely be selected and both the input and output shaft would turn when in gear. It calls for it in the manual so checked it both of on and off the bike.

The clutch was taken apart as the plate eith the splined section that the input shafts sits into was worn and needed replacing. I'm confident it was put back together in the same position it came off. It was marked up and swapping the plate out required minimal disturbance.

I'm going to get the starter motor off again tonight and with the bike in gear, confirm that the box is still turning properly when the wheel is turned. That should eliminate the gearbox being at fault. I guess then maybe investigate the clutch rod and slave cylinder after that.

The clutch was taken apart as the plate eith the splined section that the input shafts sits into was worn and needed replacing. I'm confident it was put back together in the same position it came off. It was marked up and swapping the plate out required minimal disturbance.

I'm going to get the starter motor off again tonight and with the bike in gear, confirm that the box is still turning properly when the wheel is turned. That should eliminate the gearbox being at fault. I guess then maybe investigate the clutch rod and slave cylinder after that.

-

Rumplefunkskin

- Posts: 15

- Joined: Sat Dec 21, 2013 1:17 pm

Success!

At last, some good news! She's done! The problem with the lack of drive turned out to be the bevel box. It might not have been properly engaged with the drive shaft.....  Simple error but very annoying!

Simple error but very annoying!

Took it out for a gentle ride yesterday and it all feels and sounds fantastic. Gearbox is buttery smooth on changes. I think I could do it just with a little toe, it's that easy. Haynes manual suggests a 600 mile, 4k rpm wearing in period now, so will try and rack up some miles over the next week to try and get that past and then, it's sale time for the big Beemer.... This issues broken my spirit a bit and love for the bike. She's fantastic to ride, makes the most gorgeous noise (Vandelinde exhausts!) but having done this job, it's turned me off completely. I shall be going back to a jap twin I think. Won't be the same, but it's time to move on.

So, If anyone fancies a 2001 model R1100s with some trick goodies for the summer, do message me.

Thanks to all who've offered support, advice and knowledge. It's been a godsend, and I wouldn't have managed it without your help

Thanks,

Tom

Took it out for a gentle ride yesterday and it all feels and sounds fantastic. Gearbox is buttery smooth on changes. I think I could do it just with a little toe, it's that easy. Haynes manual suggests a 600 mile, 4k rpm wearing in period now, so will try and rack up some miles over the next week to try and get that past and then, it's sale time for the big Beemer.... This issues broken my spirit a bit and love for the bike. She's fantastic to ride, makes the most gorgeous noise (Vandelinde exhausts!) but having done this job, it's turned me off completely. I shall be going back to a jap twin I think. Won't be the same, but it's time to move on.

So, If anyone fancies a 2001 model R1100s with some trick goodies for the summer, do message me.

Thanks to all who've offered support, advice and knowledge. It's been a godsend, and I wouldn't have managed it without your help

Thanks,

Tom

-

Rumplefunkskin

- Posts: 15

- Joined: Sat Dec 21, 2013 1:17 pm

Awwww crap. Seriously??? Went over a pothole this morning, and the bike jumped and started making a vague but not too loud) rubbing noise somewhere from the drive train. Taking it gently to get home as only 2 minutes away and when decelerating, the bike jumped again but with a bang this time. Stopped immediately and wheeled it the rest of way home. Bike was making a rubbing noise in neutral as it was being pushed along. In gear it felt as though the box was 'locking' itself at a certain point. i.e. the gearbox would rotate so much in either direction before hitting a stop, presumably by whatever went bang inside.....

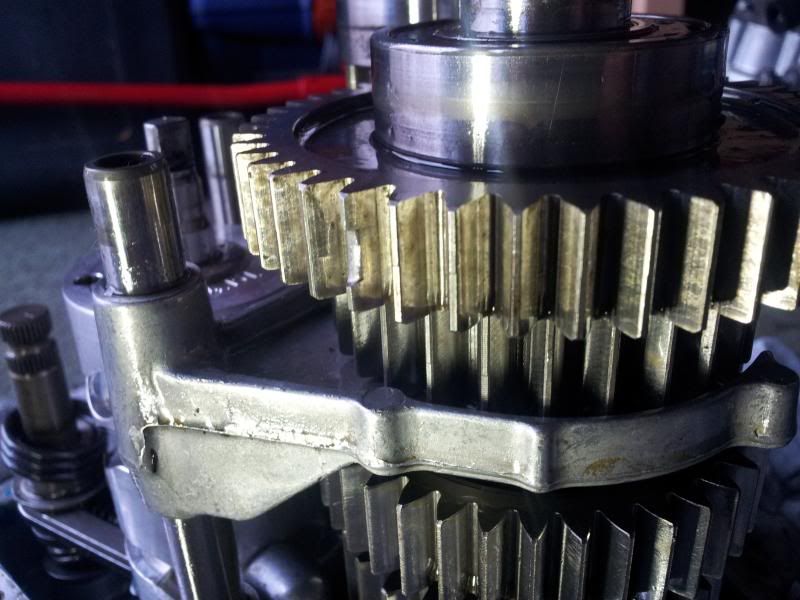

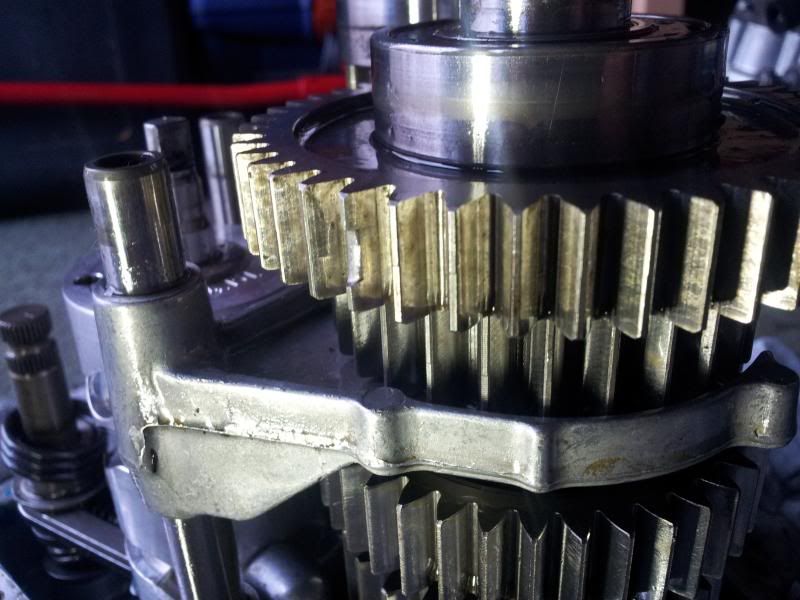

Ripped it all apart this morning (getting good at this!) to find......:

There must still be some pieces floating around inside the box that I can't see. I've cleaned a few out, and the mag plug caught a load, but something is still stopping the output shaft from travelling through a whole rotation properly. Something, somewhere is caught within the teeth I think.

So that'll be two replacement gears to add to the list as well. So fed up of this bike now. Need it gone now, but can't get rid of it until it's fixed, as I need the capital invested in it. Not good.

Ripped it all apart this morning (getting good at this!) to find......:

There must still be some pieces floating around inside the box that I can't see. I've cleaned a few out, and the mag plug caught a load, but something is still stopping the output shaft from travelling through a whole rotation properly. Something, somewhere is caught within the teeth I think.

So that'll be two replacement gears to add to the list as well. So fed up of this bike now. Need it gone now, but can't get rid of it until it's fixed, as I need the capital invested in it. Not good.